Metal welding: definition, processes and types

Metal welding comprises a number of different techniques that can be used to create a broad range of components, varying in size, shape, and weight. Discover how the metal welding process works, the advantages of this method, and how to deal with thin sheets.

Metal welding is a process that allows the manufacture of perfect parts that can be assembled to create a finished product. It is a fundamental stage of the production cycle of several industries: from automotive to aerospace, and infrastructure.

Welding metal is a complex and technical activity which requires highly skilled professionals in order to successfully work with different materials.

Furthermore, metal welding involves dealing with the effects of heat and pressure over sheets while acquiring in-depth knowledge of each technique and the properties of each material.

On this page, we will delve into:

- What is the metal welding process, and how does it work?

- There is not only a metal welding method

- All the pros and cons of welding metals

- How to weld metal sheets

- How to use the MIG metal welding technique for thin metal

What is the metal welding process, and how does it work?

The metal welding process is a preferred method when it comes to the production or repairing of metal parts. It consists in assembling components by melting pieces, securing the joint through a filler material.

Welding can be performed by using several energy sources, including:

- gas flame

- electric arc

- laser

- electron beam

- friction

- ultrasound.

The sources vary based on the type of metalworking required, the nature of the selected materials, the features that the welded metal should display, and the surrounding environment.

There is not only a metal welding method

Surprisingly, there are many types of metal welding that encompass a variety of techniques that can be customized based on the project and the materials involved. As a matter of fact, having an array of methods to choose from helps tailoring solutions for different applications.

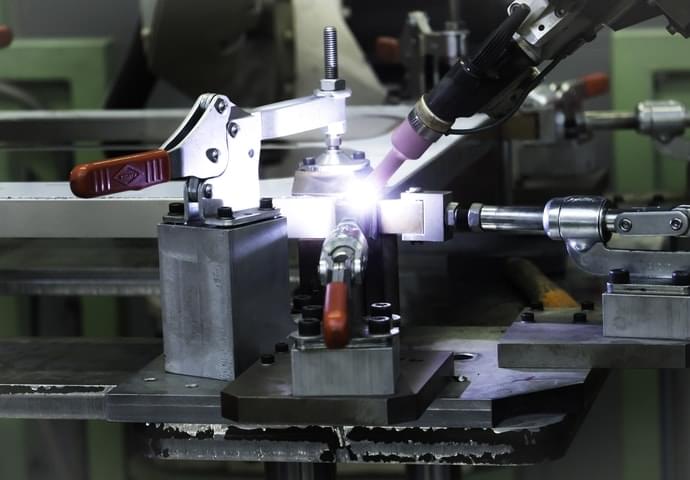

Welding metal using the MIG technique

MIG, also known as Metal Inert Gas welding, is the most common and efficient method. It consists in heating metals to make them more malleable while an electric arc shoots the filler material. During the process, a continuously feeding wire is melded with the edges of the metal. In this case, gasses play a crucial role, as they act as a shield to protect the arc and the welding zone from external agents that could contaminate the working environment.

The MAG metal welding process

The MAG - the acronym for Metal Active Gas - welding process is similar to the MIG technique. Instead of using inert gasses, MAG uses active shielding gasses that play a part in the reaction and could change the entire result of the process. During the MAG procedure, the selected gasses are often mixtures of Argon and Carbon Dioxide.

TIG metal welding

The TIG metal welding process is also known as Tungsten Inert Gas. It is a method which employs a non-consumable tungsten electrode protected by an inert gas. This procedure can be performed with or without the filler material.

The welder inserts the tungsten electrode into the flashlight, which is surrounded by the shielding gas while being brought onto the melting bath.

TIG offers a higher level of precision and control over the various elements involved.

Other welding metal techniques

There are other welding metal methods that can be used, such as:

- Electrical resistance consists in merging two conductive metal components together in order to let heat allow the passage of electrical power.

- Laser is a technique which joins metal components together by using a laser beam.

All the pros and cons of welding metals

There are intrinsic advantages and disadvantages of welding metals that need to be addressed in order to acquire new skills and knowledge about the process itself.

MIG/MAG

Although being extremely advantageous quality and budget-wise, these metal welding processes could result in an end product with some aesthetic imperfections. They are particularly effective in environments that require a high production rate.

TIG

This welding metal method gives the operator’s full control over the process, enhancing the overall precision of the procedure that can be used to manufacture components for many different applications. On the other hand, customization levels are higher and the process itself requires more time to be performed.

Resistance metal welding

The main advantage of resistance metal welding technique is fast. It is suitable for the mass production sector but, nevertheless, it requires large spaces to be performed.

Laser metal welding

This is the ideal choice for those professionals who are looking for the perfect combination of aesthetics and resistance. Only highly-skilled experts with a deep knowledge of the laser technique can approach this metal welding method.

How to weld metal sheets

Nowadays, with the technological know-how acquired and the variety of techniques, metal welding has become more customizable based on the type of alloy or application.

To obtain excellent results in the sheet metal welding process, it is important to:

- Align the process with the chosen materials. Due to the introduction of more advanced technology, now it is possible to match metals with the appropriate welding method, in order to preserve the properties and features of the sheets.

- Select a competent welding partner. When it comes to choosing a trustworthy company to perform the metal welding process, it is crucial to consider certain aspects, such as the machinery used, the overall level of technology implemented, and the team’s know-how to provide you with the best sheet metal outcome.

- Conduct a pre-production metal test. Before starting the metal welding production, Minifaber always creates prototypes to check the final quality of the product.

- Monitor the temperature. Especially in sheet metal welding, heat plays a critical role. Checking the temperature effectively guarantees optimal results while preserving the operator’s welfare. This is particularly true when the welding process involves thinner and more ductile metals.

How to use the MIG metal welding technique for thin metal

Welding sheet metal with the MIG technique is the most suitable for thin metal. It can be performed with or without gas protection, the latter implying the use of a flux or solid wire. As it is carried out on thin metals, CO2 is not recommended as it reaches higher temperatures than Argon, which is preferable.

If the procedure is gasless, the selection of the right wire becomes central.

- Solid wire is metallic, and it is selected once the material used for welding is defined. During the procedure, solid wire can have a cleaning action over the surface of the welded material.

- Flux wire is similar to a coated electrode. It is filled with granules that provide gas protection. There are many types of flux wire based on the requirements.

Minifaber designs and manufactures metal moulds for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber has evolved to become the only company able to design and manufacture the complex, assembled end products no one else can.

Find out more