Trumpf laser cutting in Minifaber

When it comes to laser cutting technology, Trumpf is the name that comes immediately to mind. Here are the reasons why we have included Trumpf laser cutting equipment in our fleet.Trumpf is a family-owned company and one of the largest manufacturers of machine tools, lasers and electronics for industrial processing. Among the Trumpf machines, the 3D laser cutting systems stand out: they are designed for those who need to cut components, profiles or other shapes not only in 2D but, in fact, also three-dimensionally.

In Minifaber, we have enriched our fleet with some 7000 Series Trumpf laser cutting machines, suitable for laser cutting and welding on both 2D and 3D components.

The machines we have chosen are complete systems, in which all the parts are perfectly harmonized with each other and thus produce a perfect result; moreover, they have a modular structure: it is easy to position them where needed at a certain moment, and then move them to another production department according to our needs.

On this page:

- TruLaser Cell Series 7000

- The advantages of sheets laser cutting with Trumpf implants

- Minifaber's laser cutting experience

Trumpf laser cutting: TruLaser Cell Series 7000

What are the practical characteristics that make it worth choosing a Trumpf - 7000 Series? Five are those that convinced us: speed, intelligence, automation, efficiency, comfort.

- Cutting speed. The TruLaser Cell 7000 systems are able to perform cuts up to 40 meters / minute.

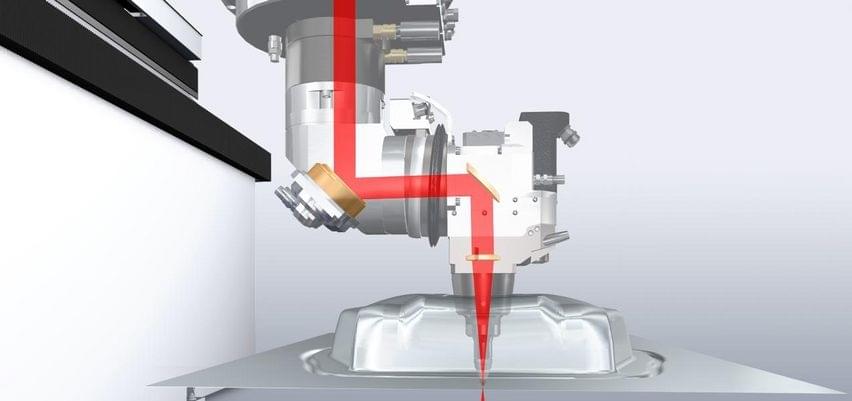

- Intelligent optical system. Thanks to the integration of a magnetic coupling, the optical systems avoid collisions and ensure that the machine is always mounted in the right optic.

- Automatic adjustment of the focal point. The laser beam works homogeneously and calibrated throughout the work area: errors and smudging are reduced to a minimum.

- Double system: laser cutting and welding. The Fibra 2in1 system allows cutting and welding with a single optical fiber cable. The transition from laser cutting to welding happens in a few seconds, thanks to a quick setting of the machine.

- Ease of use. The ergonomic and rotating control panel and the 6D mouse increase the ease and convenience of use.

These 5 characteristics allowed us to personally test other 2 important advantages.

Advantages of sheets laser cutting with Trumpf implants

The cutting speed, together with the simplified setting, reduce both production and dead times: productivity is very high. Precision is given instead by optical systems and automation systems, which minimize the possibility of errors during processing.

Speed and precision, together, amplify their benefits and create an even greater one: the reduction of processing costs. Add the limited maintenance costs (no superfluous lubrication cycles, thanks to centralized lubrication) and what you get is a machine with exceptional performance.

Our Trumpf laser cutting experience

In Minifaber we have chosen to integrate our fleet with the TruLaser Cell 7040 model.

The positive effects on the productivity of the sheet laser cutting department were immediate:

- Reduction of grinding and finishing times;

- Simplification of logistics. By fitting the partition, we have separated the work station into two parts, one dedicated to laser cutting, the other reserved for loading and unloading semi-finished and finished pieces;

- Technological adaptation of obsolete processing;

- Cost reduction.

Would we recommend Trumpf laser cutting facilities? The answer is, surely, yes.