Metal forming and punching company

With more than fifty years of experience, our company can assist you with any metal forming and punching process. On this page, you will find Minifaber’s services in sheet metal working, dedicated to the worldwide market.With more than fifty years of experience, our company can assist you with any metal forming and punching process. On this page, you will find Minifaber’s services in sheet metal working, dedicated to the worldwide market.

Minifaber is a metal forming and punching company that performs work on both large and small quantities: from the design and construction of dies and equipment for welding and assembly to laser cutting and punching operations. Thanks to our established expertise, we are able to meet the customer's needs to carry out the most required metal processing.

Here are the topics you will find on this page:

- What processes can we deal with?

- Our company’s machinery

- What metals we can form and punch

- Applications

- Why choose Minifaber

What processes do we deal with as a metal forming and punching company?

Minifaber has the necessary skills and technologies to carry out various metal forming and punching processes on metals, including complex ones. These include:

- Mold design and construction: Minifaber takes charge of designing and constructing custom molds for the production of machined objects, starting with sheet metal.

- Metal blanking: among the metal forming processes in the company, Minifaber carries out the blanking process in-house; a real separation of metals made through punches and dies.

- Metal deep-drawing: through the cold-drawing process, our company performs sheet metal deep-drawing, that is, the deformation of sheet metal to create three-dimensional concave, cylindrical or box-like shapes.

- Metal bending: by exerting pressure through a bending machine, Minifaber is able to bend flat sheet metal to obtain different shapes, usually on semi-finished products.

- Metal punching: Minifaber is a metal punching company with huge know-how. We use 4 punching machines and a deburring machine to make holes, cuts, and shapes in sheet metal, through mechanical pressure exerted by metal punches.

- Metal laser cutting: thanks to 4 combined numerically controlled punching machines, our company guarantees the precision of sheet metal laser cutting, which is ideal for creating ultra-high precision cuts.

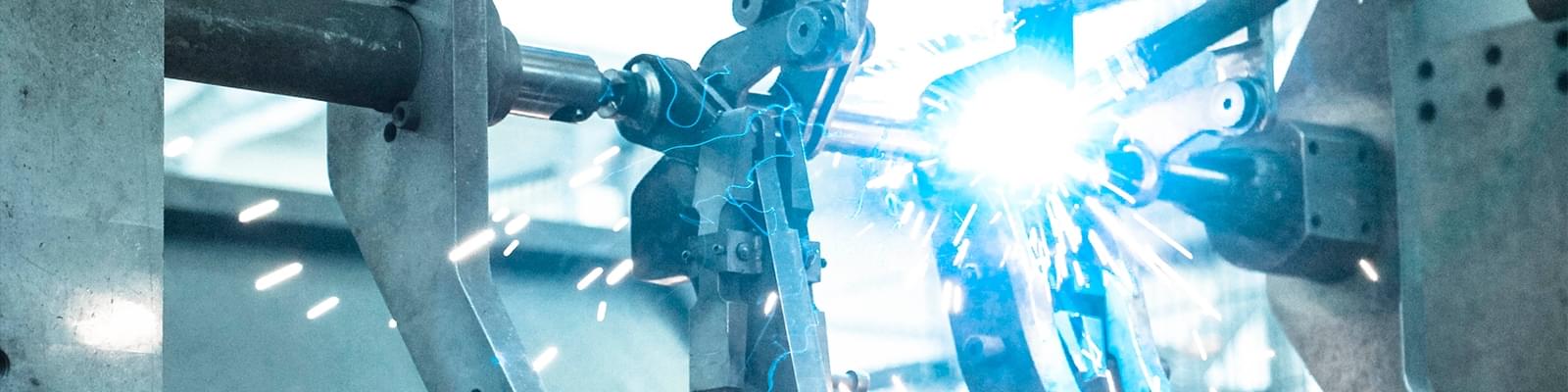

- Metal welding: thanks to its flexibility in metal forming, Minifaber is able to perform sheet metal welding following different techniques, suitable for different applications.

Our machinery for metal forming and punching

Our company has invested in new technologically advanced forming machinery. Our machinery is not only capable of reducing production time but is also designed to make extremely accurate and quality machined and semi-finished parts. With the addition of a robotic tool changer, our metal forming and punching machinery allow for extremely fast setups and seamless format changes to speed up forming processes.

For metal punching, we use the CNC punching machine. CNC stands for Computer Numerical Controlled and means that the machine is instructed to manage the sheet metal into the correct position under the punching ram. From there, the machine produces holes at high precision and speed.

What kind of metals can our company punch?

Our company performs punching and forming operations on different types of metal. Below you will find out what metals we can work on and the characteristics of each metal to consider when choosing the most suitable process.

Steel

At Minifaber we offer our customers a reliable forming and punching service for steel and stainless steel. This material, due to its hardness, requires more pressure to be machined.

Aluminum

The strength of aluminum is lower than that of other metals, such as iron and steel, but this does not preclude the need for detailed care in all sheet metal processing, including forming and punching. Precisely because of its malleability, utmost precision is needed in aluminum machining.

Iron

Iron processing, given the high strength of the metal, must be done with the correct tools. Our company has machinery suitable for all types of iron processing, from punching to blanking and welding.

Copper

The natural ductility of copper allows for meticulous machining and shrewdness that prevents unwanted deformation on the metal being worked, or the formation of sharp edges and irregularities.

Applications of metal forming and punching

Our company forms and punches metal for the following industries:

- Electromechanics

- Vending

- Kitchen robots

- Medical

- Gas distribution

- Professional lighting

- Home appliances

Minifaber is a company that, thanks to fifty years of know-how in cold sheet metal forming and punching, continuous investment in technology, and a customer-oriented approach to listening, is capable of making complex finished and assembled parts that no other company can get.

Why can we offer an outstanding service in metal forming and punching

There are some features that differentiate us from the rest of the market. For instance, in our company molds intended for metal forming and punching are designed in-house, and the production of punched, drawn, and bent parts, as well as the assembly of semi-finished and finished products, also takes place in-house. The customer comes to Minifaber with his own technical drawing, or even just his own idea of a part to be made, finds a team of professionals and a technology park that allows him to leave the company with the perfect finished or semi-finished part for his production needs.

The strategic and technological heart of the company is, in fact, solid know-how, professional human resources, continuous investment in innovation, and a constantly updated and multi-specialized machine park.