Breadcrumb

Metalworking for the energy distribution sector

Strongly linked to the electromechanical industry, in which we have been operating for more than 60 years, this sector requires state-of-the-art technological solutions and absolute excellence in quality standards.

Minifaber's established experience enables it to support customers in implementing critical components essential to ensuring the efficiency and safety of power distribution systems.

Thanks to our integrated approach, we can manage every stage of the production process, from sheet metal cold processing to the manufacture of complex assemblies, ensuring customized solutions to meet the most specific needs.

Our expertise serving the energy distribution industry

For our clients in the energy distribution industry, we deal with:

- Customized components: We produce molded, hydroformed, and possibly welded enclosures and parts used in power transformation and distribution systems.

- Absolute precision: Our machining operations guarantee exacting tolerances, essential for properly integrating components into complex systems.

- Advanced assemblies: We offer finished products, ready to be installed, optimizing our customers' production chain.

Innovation for a growing industry

In recent years, the power distribution industry has been driven by the increasing demand for more sustainable and reliable solutions.

Minifaber, thanks to its ability to innovate and the flexibility of its fleet of machines, is able to meet these challenges with solutions that combine technology, precision, and sustainability.

Our collaboration with industry leaders has enabled us to develop products that improve energy efficiency and reduce environmental impact, confirming our role as a strategic partner for those operating in this ever-changing market.

Relying on Minifaber means choosing decades of experience, unique expertise in the electromechanical industry, and an unwavering commitment to innovation in the service of power distribution.

Need a metalworking quote for the power distributor industry?

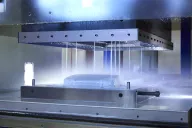

EV Charger

A customer, a leader in the latest generation of electric vehicle chargers (EV chargers), was looking for a supplier who could make the outer shell for one of its most advanced models.

Thanks to our experience and expertise, we offered ourselves as a partner for the co-design of the product, managing the entire production process.