Breadcrumb

Metalworking for the electromechanical sector

Minifaber has over 30 years in sheet metal working for the electromechanical sector, during which it has manufactured components for medium-power switches, disconnectors, drive shafts, and components for electrical panels according to customer specifications.

How Minifaber operates in metalworking for the electromechanical industry

Minifaber's goal is to integrate different materials, technologies, and processes, creating complex, assembled products that must guarantee the highest levels of safety.

Thanks to its collaborative approach with the technical departments of its multinational customers, Minifaber has earned a reputation as an excellent, competent, and reliable partner, capable of listening, discussing, and guiding its customers toward the design and manufacture of customized products.

We are able to meet the specific needs and to face specific challenges of the metalworking sector, even the most complex ones.

Do you need a quote for sheet metal fabrication in the electromechanical industry?

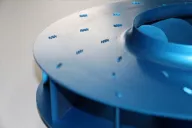

Electrical substations operating shaft

One of our long-standing customers challenged us with managing the entire production process and product range, ensuring high quality and technical standards, even in widely varying batch sizes. In particular, the design required adherence to extremely tight tolerances for the position of welded parts on cylindrical components, reflecting the complexity and precision required.