MIG welding

What is MIG welding? When is it suggested? What is the difference between MIG and MAG? What are the advantages of MIG welding compared to other processes?

Do you need to process a quantity of metals and are you looking for information about MIG welding? Here we give you all the explanations you need:

- First of all, we clarify what MIG welding consists of

- Then, we explain the difference between MIG and MAG

- We list the main applications of MIG welding and its advantages.

>> What do we mean by MIG welding?

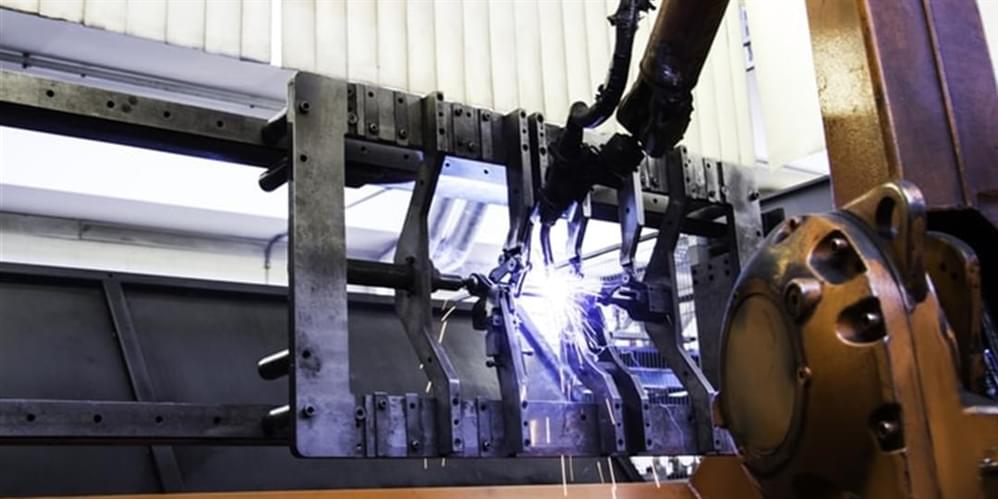

MIG welding is a type of continuous wire welding, i.e. a welding process in which the heat is produced by means of an electric arc that strikes between the work piece and a fuse wire, thanks to a torch that constantly supplies it. The wire, in MIG welding, is both an electrode and a filler material to the joint.

What is the difference between MIG and MAG welding?

In order to ensure that the electric arc is stroke and kept between the wire and the metal to be welded, and to prevent air from contaminating the welding bath, a protective atmosphere must be created: in welding under gas protection, as in the case of MIG and MAG welding, the atmosphere is guaranteed by a gas that flows through the torch.

- If the gas is inert (i.e. it does not participate in fusion, e.g. Argon or Helium), we are talking about MIG welding.

- If the gas is active (i.e. participates in fusion, e.g. CO2 or ArCO2 mixtures), we are talking about MAG welding.

To which metals should you apply MIG welding?

MIG welding with pure Argon, Helium or other inert gases is mainly used for welding aluminum, magnesium, carbon steel, copper and its alloys, such as bronze and nickel. MAG welding, on the other hand, with pure CO2 or mixtures of Argon and CO2, works better on iron, stainless steel, etc.

What are the advantages of MIG welding?

MIG welding is useful and advantageous in all cases where:

- High productivity required

- A certain flexibility of use is necessary: with MIG welding, it is possible to weld a wide variety of metals with different thicknesses.

- Welding in particular positions is required

- You want to get a good weld seam and as few smudges as possible.

>> Minifaber and the MIG welding service

At Minifaber we provide a metal welding service with different technologies: MIG/MAG welding, TIG welding, projection welding, resistance welding, etc. You can request our MIG welding service both for a few product lots and for large quantities; you can also decide to spread the production over several months.

In addition, you can use it both to weld sheet metal and make semi-finished products, both to create finished, complex and assembled products, which are our specialty.