Breadcrumb

Sheet stainless steel fabrication

For over 65 years, Minifaber has been fabricating with sheet stainless steel, with special attention to the properties of this metal.

On this page, we will discuss:

Stainless sheet steel fabrication: rely on Minifaber

Minifaber's fleet of machines

This is why Minifaber is a reliable partner for your projects

Stainless sheet steel fabrication: rely on Minifaber

For over 65 years, Minifaber has been cold fabricating with sheet metal, while diversifying the range of materials to choose from.

Our team of experts has in-depth knowledge of metals. Therefore, at the preliminary meeting stage, they listen carefully to the customer's needs and provide expert advice so that the proposed project can be implemented flawlessly.

Material selection is crucial at this stage because it affects final product use. Sheet stainless steel is used to produce a range of products for which the durability, suitability for food contact, and corrosion resistance of this metal can prove critical to the success of the project.

Features of stainless steel:

A steel alloy that naturally becomes coated with a chromium oxide, which allows the material to protect itself from corrosion (rust);

It is especially suitable for electromedical equipment, street or household furniture, the chemical sector, and when the product comes into contact with food.

Minifaber, professional sheet stainless steel processing services for small and large quantities.

Contact us without obligation for more information

Sheet stainless steel metal processing

Minifaber has a proven track record in sheet stainless steel fabrication for numerous customers that are the flagship of their sectors, and that put their trust in us as a reliable partner with high standards.

Minifaber, 65 years of expertize in stainless steel fabrication.

Contact us for a quote and feasibility study

COMPLETED PROJECTS

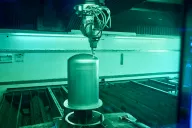

Food processor bowl

Our client initiated market research to identify a partner capable of producing a food processor bowl for one of its top lines. The request was not limited to simply implementing a drawing process, but included the need to produce a highly complex product by incorporating a number of additional operations involving advanced technologies, component assembly, and final testing to ensure a fully functional product.