Industries

Minifaber works in the most significant industries and production fields. This allows it to extend its acquired experience to a specific goods sector where it did not exist.The customer-oriented approach, the extensive know-how, focus on innovation and high quality standards are some of the factors that allowed Minifaber to be recognised and appreciated in many industrial and non-industrial fields.

Expertise ranges from the energy field to home appliances, including the medical, lighting design, vending and professional lighting industries.

Minifaber has acquired extensive experience in each of these fields where the knowledge of materials, production processes and typical industry needs allows it to efficiently and innovatively respond to customer requests on both the technical-quality and economic levels.

-

Electromechanics

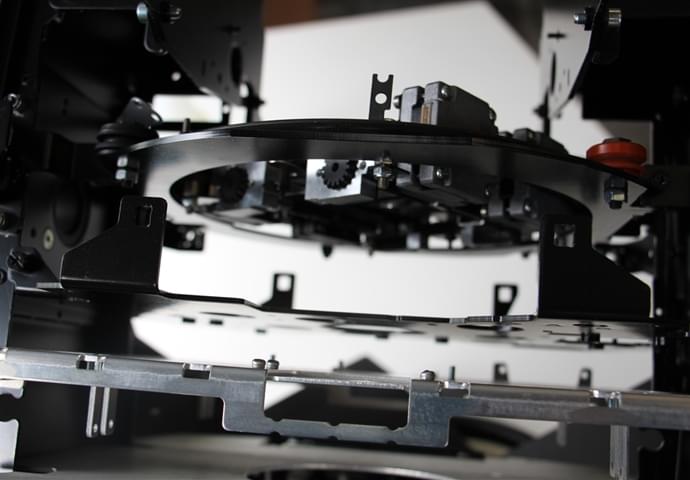

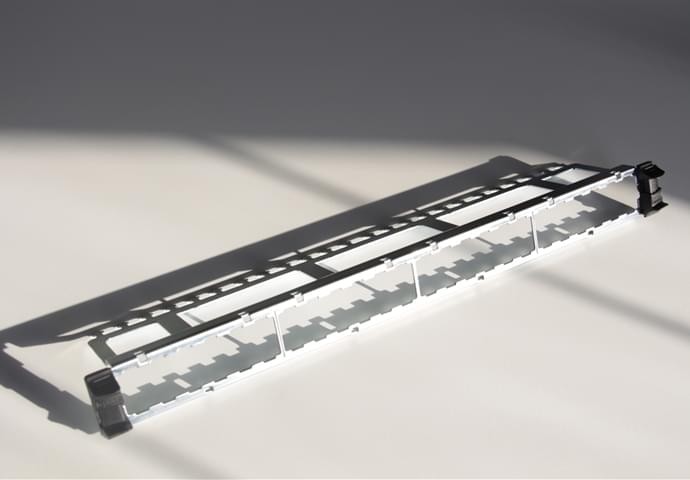

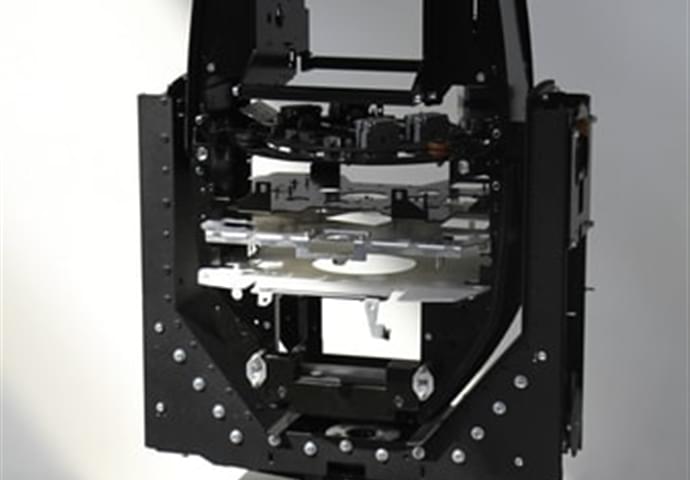

Photo 1 of Model.Gallery.CountDetail of a complex and assembled end product for the middle voltage industry.

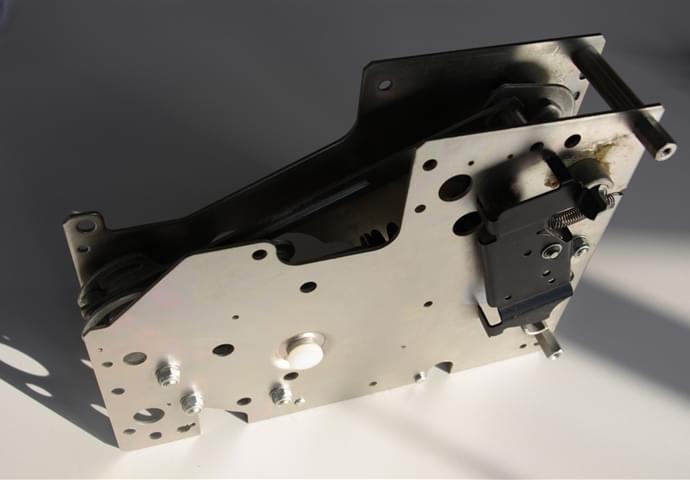

Photo 1 of Model.Gallery.CountDetail of a complex and assembled end product for the middle voltage industry. Photo 2 of Model.Gallery.CountConstruction of medium voltage switches, switch gears, control shafts and switchboard components upon customer specification.

Photo 2 of Model.Gallery.CountConstruction of medium voltage switches, switch gears, control shafts and switchboard components upon customer specification. Photo 3 of Model.Gallery.CountOne of Minifaber's focus points is the ability to integrate different materials to create complex and assembled products that need to guarantee the utmost safety levels.

Photo 3 of Model.Gallery.CountOne of Minifaber's focus points is the ability to integrate different materials to create complex and assembled products that need to guarantee the utmost safety levels.More than twenty years experience in the electromechanics industry where Minifaber manufactures medium voltage switches, disconnecting switches, control shafts and switchboard components according to customer specifications.

Extensive know-how which, combined with a flexible and innovative approach, allows the company to provide more efficient and competitive solutions to electromechanics industry customers.

One o...

Find out more -

Kitchen robots

Kitchen robots, one of those industries where Minifaber best expresses itself.

Here, the company designs and manufactures “multi-technological”; products meaning complex, finished and assembled products that no one else can today.

Due to the use of press deep-drawing techniques, highly aesthetic surface treatments and component welding, the company is able to provide en...

Find out more -

Vending

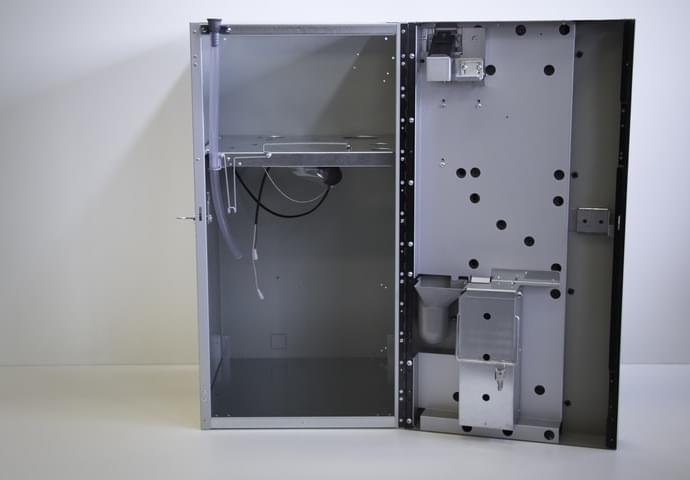

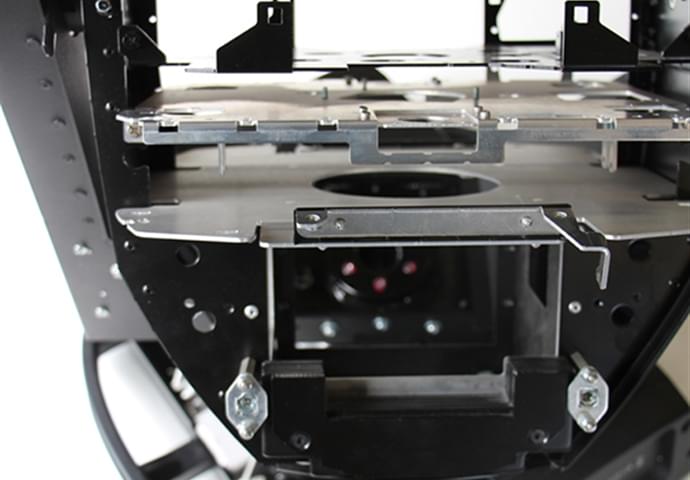

Photo 1 of Model.Gallery.CountVending is a historical industry for Minifaber that allows it to express its savoir-faire in the construction of machine parts intended for vending machines.

Photo 1 of Model.Gallery.CountVending is a historical industry for Minifaber that allows it to express its savoir-faire in the construction of machine parts intended for vending machines.Vending is a historical industry for Minifaber that allows it to express its savoir-faire in the construction of machine parts intended for vending machines.

Here, blanking, bending and welding are three processes that work together to create beverage vending machine bodies and internal parts.

One of Minifaber's added values in this field is its ability to meet ...

Find out more -

Medical

Photo 1 of Model.Gallery.CountMinifaber manufactures complex products for the medical industry such as the 17 and 22-litre pressurised steam steriliser for medical instruments.

Photo 1 of Model.Gallery.CountMinifaber manufactures complex products for the medical industry such as the 17 and 22-litre pressurised steam steriliser for medical instruments. Photo 2 of Model.Gallery.CountMinifaber performs simple processes and creates complex and assembled end products for the medical industry.

Photo 2 of Model.Gallery.CountMinifaber performs simple processes and creates complex and assembled end products for the medical industry. Photo 3 of Model.Gallery.CountSpecific know-how for the production of complex parts and assemblies that meet medical industry needs.

Photo 3 of Model.Gallery.CountSpecific know-how for the production of complex parts and assemblies that meet medical industry needs.Our experience in manufacturing products that must receive TUV certification for pressurised items and the availability of laser welding have allowed Minifaber to become a strategic partner for many companies in the medical industry.

Specific know-how for the production of complex parts and assemblies that meet medical industry needs.

Furthermore, thanks to the re...

Find out more -

Gas distribution

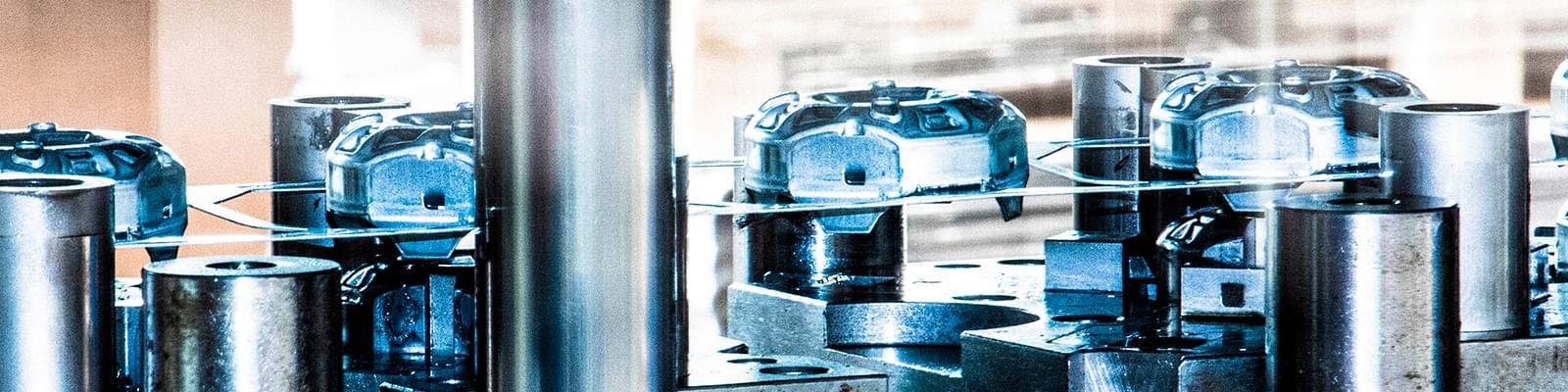

Photo 1 of Model.Gallery.CountDeep-drawn, welded and surface treated parts in which gas passage is the key factor.

Photo 1 of Model.Gallery.CountDeep-drawn, welded and surface treated parts in which gas passage is the key factor. Photo 2 of Model.Gallery.CountMinifaber manufactures blanked, moulded and bent parts as well as more complex products to construct multiple gas valves for the gas distribution industry.

Photo 2 of Model.Gallery.CountMinifaber manufactures blanked, moulded and bent parts as well as more complex products to construct multiple gas valves for the gas distribution industry. Photo 3 of Model.Gallery.CountMinifaber manufactures blanked, moulded and bent parts as well as more complex products for the gas distribution industry.

Photo 3 of Model.Gallery.CountMinifaber manufactures blanked, moulded and bent parts as well as more complex products for the gas distribution industry.Minifaber manufactures blanked, moulded and bent parts as well as more complex products to construct multiple gas valves for the gas distribution industry. Deep-drawn, welded and surface treated parts in which gas passage is the key factor.

Products where tolerance and surface quality are extremely important to guarantee the safety the product must provide.

Find out more -

Professional lighting

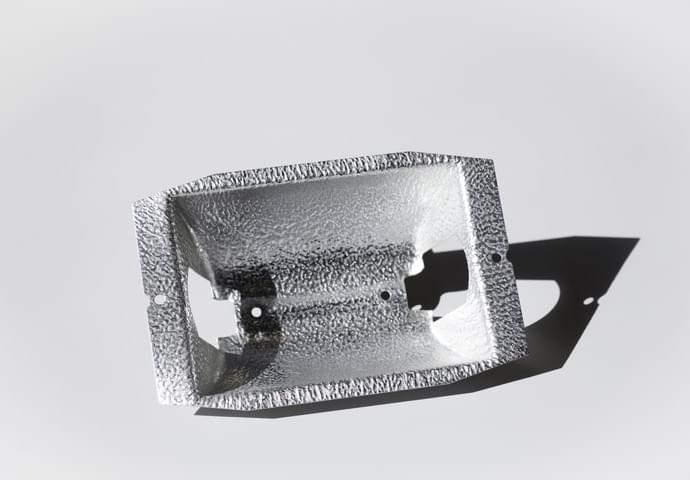

Photo 1 of Model.Gallery.CountMinifaber performs simple processes and creates complex and assembled end products for the professional lighting industry.

Photo 1 of Model.Gallery.CountMinifaber performs simple processes and creates complex and assembled end products for the professional lighting industry.One of the products Minifaber contributed in with numerous blanked, bent and finished parts lit the London stadium during the 2012 Olympics.

Professional lighting is a strategic industry for Minifaber. An industry for which the company has gained extensive experience that allowed it to understand the continuously evolving needs.

In professional lighting, material performance is always incr...

Find out more -

Home appliances

Photo 1 of Model.Gallery.CountAn example of a complex and assembled end product created through blanking, bending, plastic assembly and pre-mounted part assembly processes.

Photo 1 of Model.Gallery.CountAn example of a complex and assembled end product created through blanking, bending, plastic assembly and pre-mounted part assembly processes. Photo 2 of Model.Gallery.CountMinifaber manufactures complex and highly aesthetic parts for the home appliance industry.

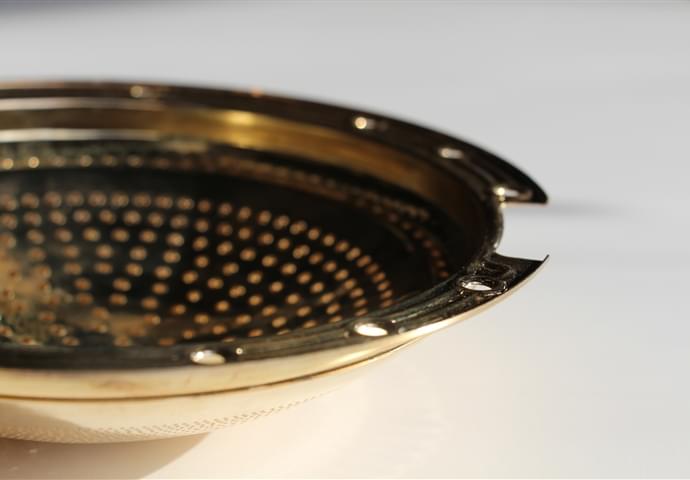

Photo 2 of Model.Gallery.CountMinifaber manufactures complex and highly aesthetic parts for the home appliance industry. Photo 3 of Model.Gallery.CountThe espresso coffee machine is Minifaber's crowning achievement in the home appliance industry.

Photo 3 of Model.Gallery.CountThe espresso coffee machine is Minifaber's crowning achievement in the home appliance industry. Photo 4 of Model.Gallery.CountThe light carpentry department and tooling department for pilot moulds are able to design and construct metal semi-finished parts and finished products for the home appliance industry.

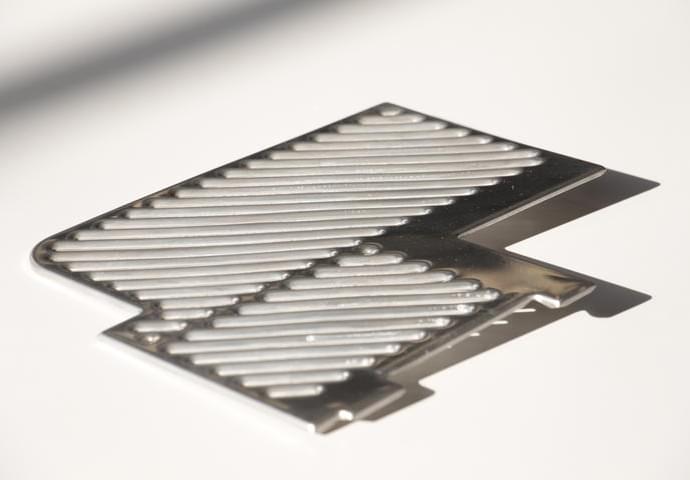

Photo 4 of Model.Gallery.CountThe light carpentry department and tooling department for pilot moulds are able to design and construct metal semi-finished parts and finished products for the home appliance industry. Photo 5 of Model.Gallery.CountMetal part used in the construction of a complex and assembled end product.

Photo 5 of Model.Gallery.CountMetal part used in the construction of a complex and assembled end product. Photo 7 of Model.Gallery.CountFor the home appliance industry, Minifaber manufactures moulds suited to this type of aesthetic need and is able to provide all prototyping processes.

Photo 7 of Model.Gallery.CountFor the home appliance industry, Minifaber manufactures moulds suited to this type of aesthetic need and is able to provide all prototyping processes.The espresso coffee machine is Minifaber's crowning achievement in the home appliance industry.

In fact, the company manufactures a complex and assembled end product with high added value. The components, made of satin or mirror polished stainless steel, have excellent aesthetic yield, as well as the metallic components assembled with plastic parts.

For the home appliance industry...

Find out more