Transfer dies vs progressive dies: differences and advantages

Minifaber is capable of producing pressed parts using both transfer dies and progressive dies. The choice between one or the other is made by the technical department based on its knowledge of the facts, and is aimed at optimizing the resources in order to allow for the production of increasingly complex and high-performance products. The parameters that are taken into consideration when choosing the most suitable die are described below.

1. The complexity of manufacturing the die

With a transfer die, each phase of the pressing process is carried out with dies that are independent of one another, so a single transfer die has a rather simple design, and doesn’t require a sheet guide, a lifter, or any of the other components required for a progressive die.

2. The type of production

Obviously, the more technically complex a die is, the more it will cost, and the more production will be required to amortize its cost over time. Therefore, the possibility of manufacturing a progressive die can be evaluated for the production of large numbers of products, while a transfer die is more cost-effective for smaller batches.

3. The need to remove the base material

With a transfer die, each work phase is separate from the others, and the material is moved using mechanical arms. During these movements, therefore, the base material can be eliminated from the pressed part starting with the first stroke of the press, without having to wait for the final shearing operation, as is the case with progressive dies.

4. The processing speed

Production with a progressive die is much faster than with a transfer die, because the semi-finished material advances through the various pressing stations autonomously, thus optimizing the time frames and allowing one or more pressed parts to be obtained with each stroke of the press.

5. The dimensions of the pressed parts

Notwithstanding the fact that both transfer dies and progressive dies can be used to obtain pressed parts of any size, transfer dies are generally considered more suitable for producing large parts, and progressive dies are considered more suitable for producing sets of smaller components.

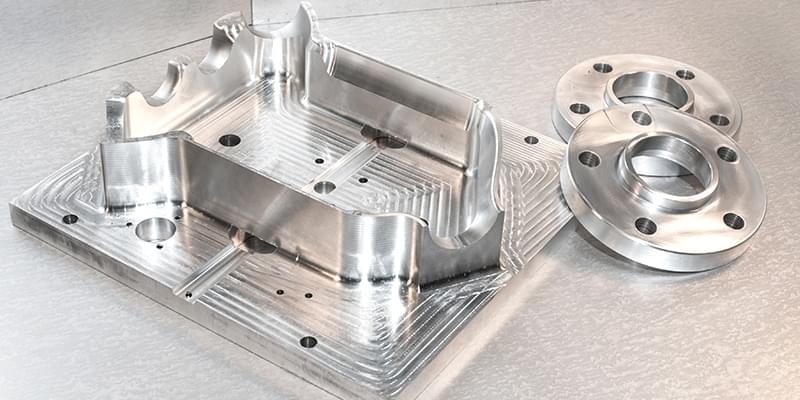

How is a mould built? Find out in this in-depth about the stamping molds process.