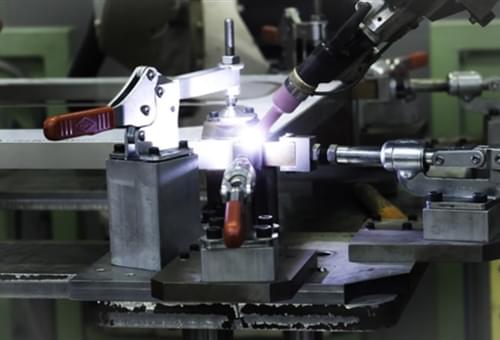

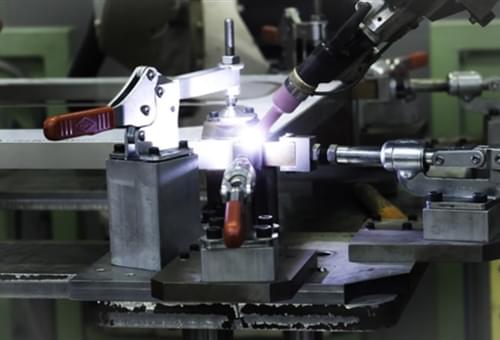

TIG welding sheet metal: perfect to weld ...

TIG welding is particularly suitable for welding thin sheet metal and can be used for both continuous and spot welding. Learn more about its features.

read more

TIG welding is particularly suitable for welding thin sheet metal and can be used for both continuous and spot welding. Learn more about its features.

read more

How to choose the most suitable welding for aluminum? There are several aspects to consider before and during the process to avoid miscalculations and processing irregularities. Let's find out about them together.

read more

A short and easy guide for beginners through the world of sheet metal stamping. Discover how the process works, which different kinds of services it includes and how we perform it in Minifaber for a full customized service.

read more

TIG (Tungsten Inert Gas) or GTAW (Gas Tungsten Arc Welding) welding is one of the most suitable processes for welding aluminum and its alloys, because it offers excellent performance and great aesthetic results. Find out in this article everything you need to know about TIG welding of aluminum and Minifaber's services.

read more

The laser allows for narrow and deep metal welding, with reduced heat deformation of the final piece. The benefits, however, don't stop there. Learn about them in this article, together with the laser welding service offered by Minifaber, which specializes in cold working various types of metals.

read more

MIG welding aluminum can become a real challenge if the appropriate machinery is not used and the process is not carried out with care. At Minifaber we specialize in metal cold working and this article will explain how this welding process takes place, what are its advantages and what services we offer customers.

read more

How is metalworking performed? How many and what are the different processes? The Minifaber team will tell you everything about sheet moulding and the services we provide.

read more

How do you professionally weld steel? What are the most common imperfections in welded joints? The Minifaber experts will tell you all you need to know about steel welding and its applications.

read more

If you need to make complex welds, even in the assembly line, the ideal method is projection welding: a particular type of resistance welding that always ensures the correct thermal balance. At Minifaber we have the necessary skills and all the machinery to perform projection welding.

read more

Iron welding is a process that involves one or more types of material with different functions: there's the base material, meaning the parts to be welded, in our case iron; and there's the filler material, meaning the material melted between the two iron parts to be joined.

read more