Stainless steel welding: safety at the forefront

State of the art sheet metal welding renders joints solid and stable over time, as well as safe, preventing accidental ruptures and contaminations that could be dangerous, or even deadly. Some examples? Here you go.

The importance of welding in the gas sector

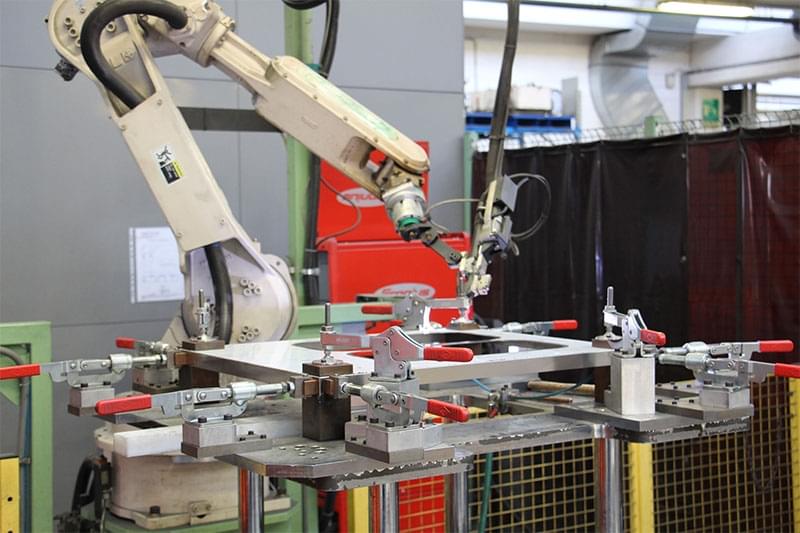

Gas meters and sleeves, both industrial and domestic, are coupled together through a welding process, which if not carried out with all due attention could cause gas leaks, with all of the associated risks, from environmental pollution to fire and explosion hazard. The robotic systems at Minifaber and the careful attention of our staff in the welding department dedicated to every process, whether stainless steel welding or sheet metal welding in general, mean that we can guarantee an excellent result and prevent accidents when the product is used.

Welding is also fundamental for products that come into contact with food

In addition to rendering the structure of the finished product stable and preventing leaks and ruptures, proper stainless steel welding in the foods sector also reduced the risk of contamination. In fact, nearly all the containers and machines destined for the foods sector are made through complex processes that include blanking, drawing and welding. If this final stage is not performed correctly, the result is an irregular, uneven weld, which when it comes into contact with food could release metallic waste materials into the food. Furthermore, porous welds can be difficult to clean and bacteria and germs can accumulate between the layers, contaminating the foods and pharmaceutical products they come into contact with.

Making a safe weld for the health of those using our products in the food and pharmaceutical sectors is one of the foundations for our philosophy. In addition to meticulously controlling the welding process, Minifaber also ensures that the chemical composition of the materials is appropriate, and we always make sure that the metals used are not only certified, but also authentic Aisi 304 and 316 stainless steel, the best materials for contact with foods and pharmaceuticals.