Stamping molds: the process in detail

The mold is a matrix which is specifically designed as a tool in some industrial manufacturing processes such as molding, casting, deep drawing, foaming or sintering: serves to give the final or intermediate form to the workpiece or the material to be processed.

In precision metal stamping, a mold is usually composed of two or more half-shells, ranging to delimit an area of the space with the shape of the piece to be obtained. The stamping of a mold is usually made of hardened steel (a thermal process to improve its characteristics), or tempered.

Molds of less resistant materials, such as chalk, or silicone resin are used for the production of small series for rapid prototyping. The useful life of a mold can go from a few pieces, or even just one, to thousands of millions of copies.

On this page you will find:

- How the stamping of molds works;

- Stamping molds by processing method of the product;

- Why choose Minifaber for stamping of a mold.

The stamping mold processes

Stamping mold is the process of making pressure on the blank so that the blank will undergo steel transformation or separation to produce workpieces with fixed sizes, shapes and properties.

The molds are made according to the processes of traditional milling or high speed, to reach the shape are used for 7-axis milling machines. The active parts of the mold are also used as electrical discharge machines (wire or tuff), lathes, and grinders.

In the precision metal stamping field, the mold must usually be designed without cavities that might restrict the removal of the piece: in particular, undercuts are to be avoided, that is, angles of 90° or more, which in fact make the printed indivisible element from the mold.

The stamp of a mold must pay particular attention to the draft angles: since the creation of the walls perfectly in axis with the extraction movement could give problems in the removal of the finished parts, the walls should never be designed vertical but must have a slight angle (1 or 2 degrees) to the outside. To exemplify, a cylinder should be converted into a truncated cone in order to be extracted without problems.

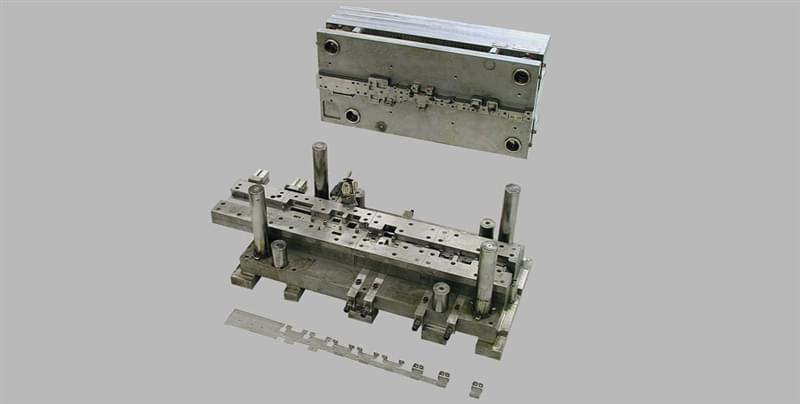

In the molding of sheet metal, the mold is made from a steel block, divided into two parts, one on the base and the other on the movable part of the machine tool, which deforms the material to obtain even with subsequent steps (and with molds gradually slightly different) the final shape of the piece industrial.

A process of precision mold stamping is known as deep drawing. It is a very difficult task, which must be divided into several steps to prevent the sheets from being stretched excessively and therefore can tear or bring thinning non-uniform.

Different types of stamping molds

According to the different stamping molds, these last can be divided into five categories: punching and shearing molds, bending molds, drawing molds, forming molds and compression molds.

- Punching and shearing dies. Commonly used shapes are shearing molds, punching molds, trimming molds and edge molds.

- Bending mold. It consists of bending the flat blank at an angle. Depending on the shape, precision and production volume of the part, there are many different forms of mold, such as ordinary bending mold, cam bending mold, curling mold, arc bending mold, punching bending mold, twisting mold and so on.

- Drawing dies. Drawing mold allows you to make a flat vacuum in a container seamlessly with the bottom.

- Forming mold. This refers to the use of various methods of forming the mold. It can be convex, curled, neck, and round edge hole flange.

- Compression mold. Uses strong pressure to flow and deform raw metal into the required shape. Its types include extrusion mold, embossing mold, and final pressure mold.

Why choose Minifaber for stamping molds

Minifaber puts at the center of its business the attention to the customer, designing and manufacturing customized molds. This is a very delicate process as the mold must fit perfectly for the purpose for which it will be used. So the process of designing and building a mold must be precise and carried out by qualified personnel, from engineers to operators.