Laser welding is one of Minifaber's services: this is what we offer

The laser allows for narrow and deep metal welding, with reduced heat deformation of the final piece. The benefits, however, don't stop there. Learn about them in this article, together with the laser welding service offered by Minifaber, which specializes in cold working various types of metals.

We’ll see...

- What is laser welding

- The types of laser welding that Minifaber performs

- The benefits of this technique

- The human factor and professionalism of Minifaber

- Minifaber’s laser welding in the world

What is laser welding

The laser welding technique requires a laser beam to be used as a concentrated source of heat to join metal elements together. By providing a high energy density in a very small area, laser technology melts the metal by only heating the piece in the area to be melted, creating narrow and deep weld beads.

The types of welds that can be obtained with the laser

Different types of welding joints can be obtained with the laser technique:

- Narrow and deep welds to ensure the mechanical strength of the joint

- Wide and shallow weld beads to ensure sealing and tightness of gas and liquid containers

- Welds that combine the two weld joints

Minifaber performs and specializes in laser welding, to provide you with products designed and manufactured according to all your needs.

The benefits of this technique

Laser welding is one of the most popular techniques in metalworking. In fact, it lets you:

- Weld components together faster than other welding processes

- Touch up faster when grinding and polishing pieces thanks to the reduced weld bead

- Achieve more precise and resistant results, without welding spatter

- Significantly reduce the deformation of the welded pieces and, consequently, the waste pieces

- Ensure greater safety in the workplace, as workers do not come into direct contact with the laser beam

The human factor and professionalism of Minifaber

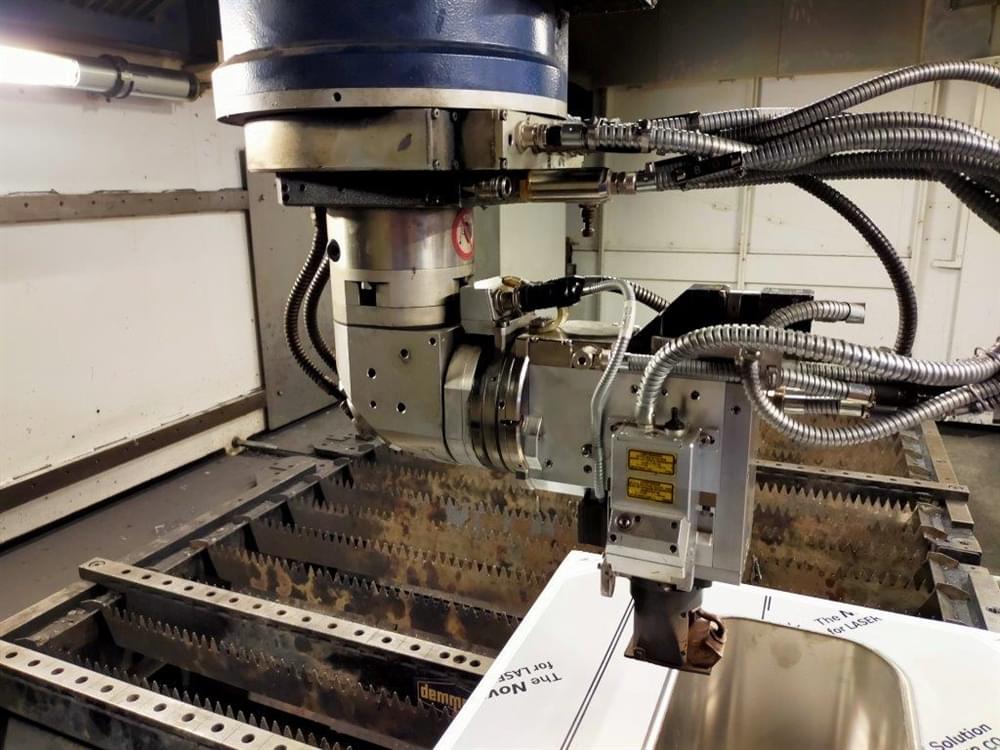

Laser welding is carried out with automatic machinery, where the human factor is not necessary for the process itself, but is essential for machine settings.

At Minifaber, for example, 2 of the 28 employees currently employed in the welding department have specific training precisely for the use of welding robots and are able to manage the entire machining process with attention and precision.

By adding the latest generation of laser welding machines to its fleet, Minifaber was able to:

- further increase the overall quality of machined parts

- meet production deadlines thanks to the almost total absence of delays due to processing errors

- improve the working conditions of department staff, another aspect that is very important to the company

Minifaber’s laser welding in the world

Minifaber is a point of reference for the world market of cold metalworking: after all, being glocal is one of the cornerstones of the company's philosophy which, from its headquarters in Seriate, near Bergamo, always seeks innovations proposed by the cold metalworking world.

The attention and curiosity for new technologies have led it to have a constantly evolving machine fleet, where the inclusion of new equipment is not dictated only by the need to increase production capacities, but corresponds to an improvement in the quality, timing and performance of each service. An example? Laser welding machinery!