Copper bending? Here's a look at Minifaber’s services and machinery

Minifaber has specialized in cold metalworking since 1960 and offers numerous services to customers all over the world such as copper punching and bending. Find out how it happens, what we offer and the technological machinery we use in this article.

Copper is one of the metals with electrical conductivity, heat conductivity, strength and malleability: characteristics that make it one of the most used and requested metals.

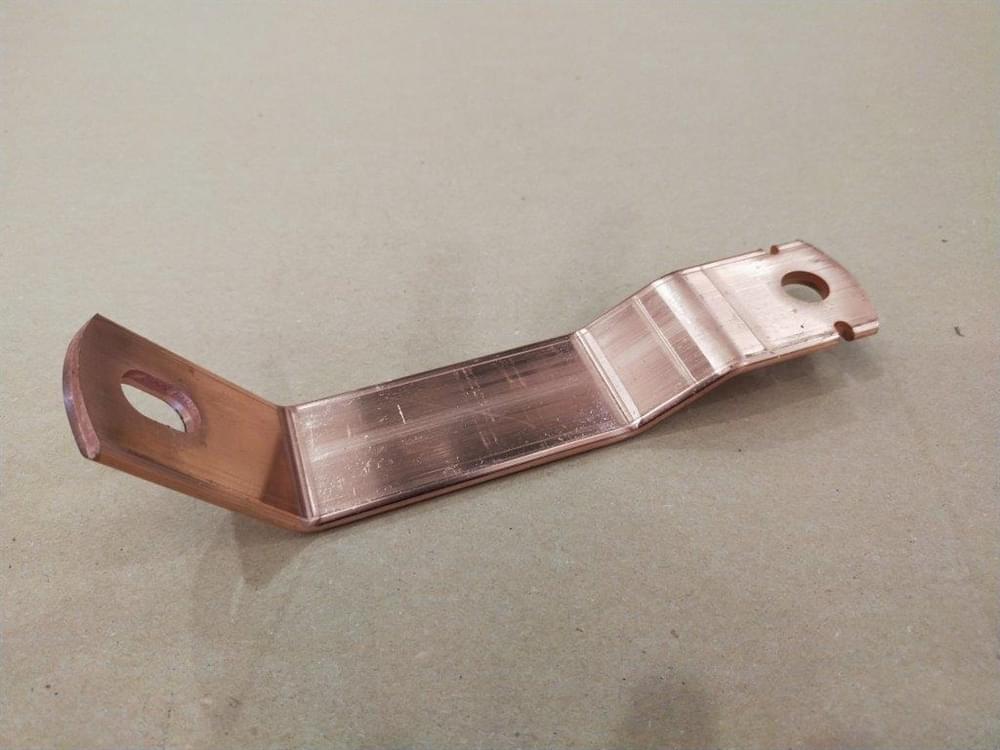

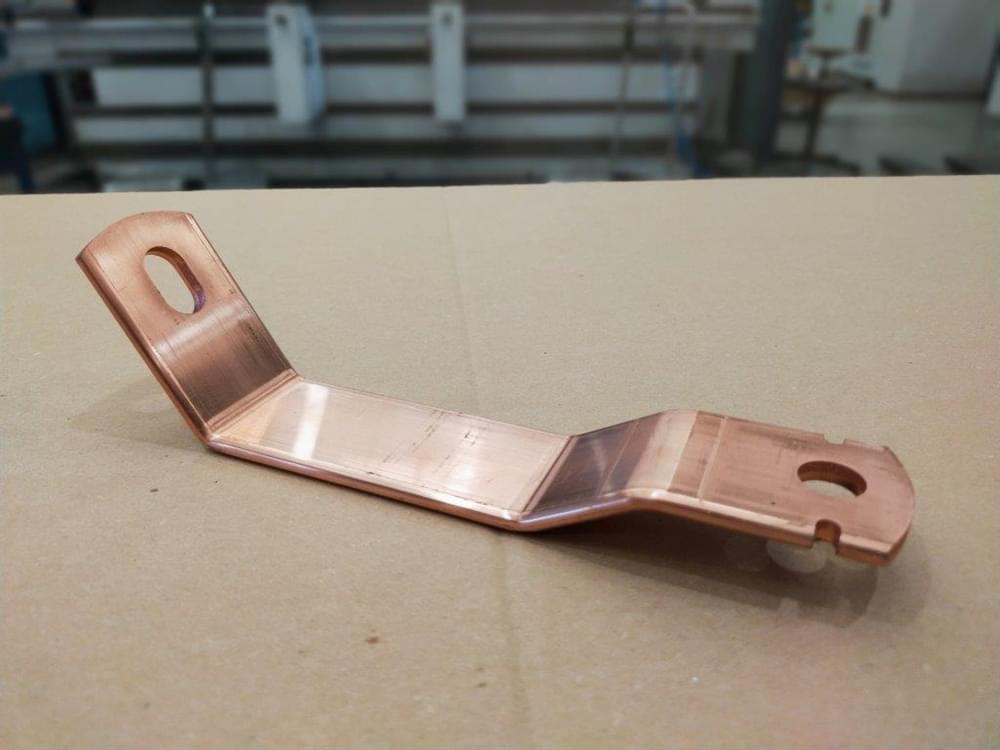

Among its myriad of services, Minifaber provides copper bending for this reason: thanks to the ductility and malleability of this metal, bending can be carried out quickly and easily, but with extremely precise results.

How is copper bent?

Copper - and other metals - are bent by a bending press where the combined action of a blade and a slot processes the sheet metal or the previously cut piece, based on the configuration chosen during the design phase.

Copper bending gives to the sheet a certain shape or reinforces some portions, taking into account fundamental characteristics, such as:0

- the radius

- the bending strength

- springback

Your needs are Minifaber’s starting point

Communicating with the customer is the first step in correct copper bending: in fact, only after having listened carefully to your needs, can we provide you with detailed feedback and the feasibility analysis of the project to achieve perfect results.

Whether you need a finished product, copper pipes or semi-finished products, our Engineering Department is at your disposal to ensure precise and error-free copper bending.

Copper bending machines

Specific programmable bending machines are required to bend copper: Minifaber has eight of them from 30 to 180 tons, plus a paneling machine.

Programmable bending machines

Using a bending machine is one of the most accurate and economical ways to bend copper - or other metals - even in small lots. With this technique, the sheet is pushed by a blade into a V-shaped groove, where it is bent.

The paneling machine

Copper bending using a paneling machine is ideal for parts that need to be bent on all four corners with complex and different bends.

In this case, the copper sheet is placed on a work surface and is clamped by the machine's sheet press while a tool bends it.